Pakistan’s foremost internationally competing drone team has made the country proud once again by winning the Runner Up Award at U.K’s IMechE UAS Challenge 2021. Team NUST Airworks is an undergraduate team based in the National University of Sciences & Technology – Pakistan Navy Engineering College, Karachi. NUST Airworks has been designing, manufacturing and testing Unmanned Aerial Vehicles (UAVs or aka drones) for the past five years.

The team comprises twenty-five electrical and mechanical engineering undergraduates from 1st to 4th year. It is a cross-functional team spread across five departments: automation, communications, marketing, mechanical and software, that work together to achieve the team’s end goals.

NUST Airworks made its mark in the national drone competition circuit from 2016 – 2018 before looking to international skies to prove its mettle. It has been competing annually in the IMechE UAS Challenge, since 2018.

Held every year in the U.K by the Institution of Mechanical Engineers, the UAS Challenge sees university teams design, build, test and fly an unmanned aircraft system (UAS) over a 9-month project cycle culminating in a live flyoff event held in the summer. The Challenge presents teams with a simulation of a natural disaster scenario, where relief aid packages must be delivered to areas inaccessible by humans.

Teams must choose an aircraft configuration best suited to competition’s missions that include a fully autonomous flight from take-off to landing, navigating the route according to ground markers and dropping the payload package accurately. Over 30 international teams from Bangladesh, Denmark, Greece, India, Pakistan, Netherlands, Russia, Sri Lanka and the U.K take part in the competition.

In its debut year in 2018, the team clinched the Highest Placed New Entrant Award along with the Media Engagement award. The next year the team returned to the U.K determined to win. Their passion and perseverance paved the way for the team to win four out of eight available awards in addition to achieving the Grand Champions Title.

The Covid-19 pandemic and resulting lockdowns forced the team to withdraw from the final stage of the competition in 2020. 2021 has been one of the team’s most challenging years, forcing the team to participate virtually in the IMechE UAS Challenge 2021.

Lockdowns resulted in the team losing their workspace for months, necessary components could not be shipped on time from abroad, and maintaining member morale was not easy with limited interaction. Despite it all, team NUST Airworks remained committed to representing Pakistan successfully once more.

The team had the second-highest cumulative score based on its submitted reports and X-Plane model across all virtual participants leading to it receiving the Runner Up Award. It also won the Safety Award, with the judges commenting that the team “gave an excellent explanation of their general approach and a good hazard table with clear consequences of concern, preventative and corrective measures.”

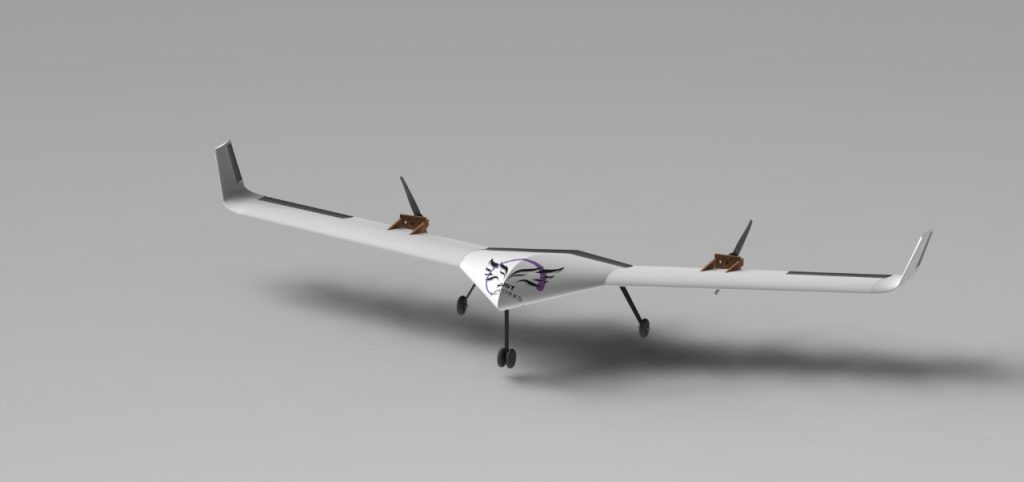

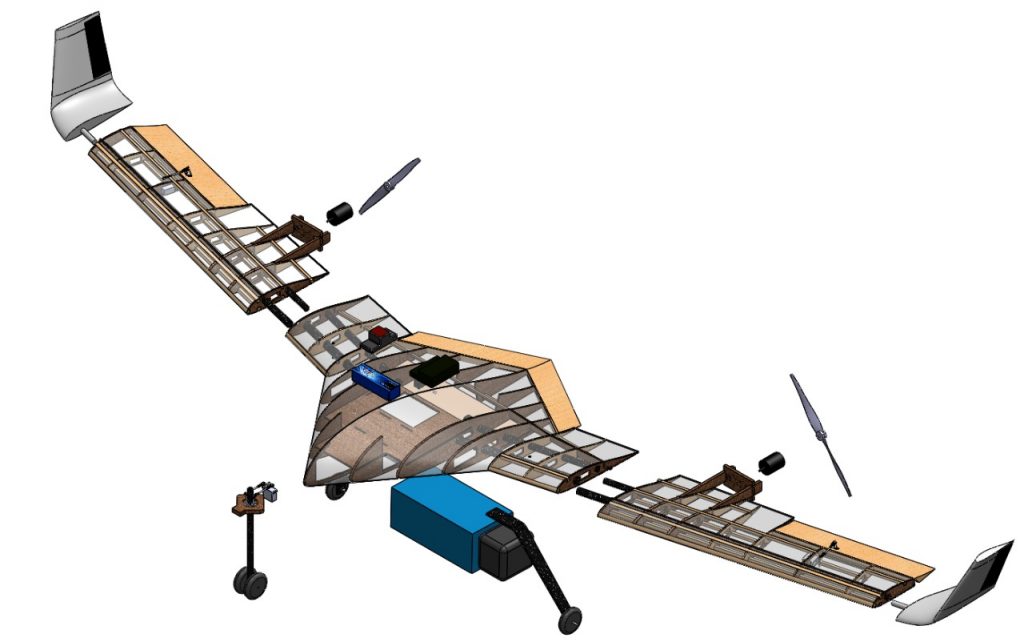

NUST Airworks has developed multiple different configurations including quadcopters, fixed-wing designs, hybrid VTOL (Vertical Take-Off & Landing), and a helicopter (Uqaab, made in 2019, was the first-ever helicopter entry in the IMechE UAS Challenge). For 2021, the team decided on a tail-less blended wing body airframe due to its suitability to the competition’s Climb & Glide mission as well as manufacturing feasibility.

The first stage in the process is the design stage. Once the main configuration is decided, XFLR and CFD performance analyses are carried out before the CAD model is finalized and further iterated after testing. For the second stage, this year the team manufactured a pink foam mould and fibreglass shell in-house. The internal structure was made up of carbon fibre spars and plywood ribs, also constructed by the members. The final stage before flight tests is automating the drone which involves calculating power requirements, configuring the auto-pilot and further fine-tuning it during test flights.

The team’s software department works in parallel to develop a neural network capable of identifying alphanumeric characters and their colours on the ground from 400 ft above. The mounted Single Board Computer transmits this information along with extracted GPS coordinates back to the ground control station.

A core value of team NUST Airworks and the IMechE UAS Challenge is to spread awareness about UAV systems and develop a passion for STEM in young minds. Throughout the year, NUST Airworks holds engaging workshops with different schools to introduce students to the dynamism of drones and encourage them to experiment with building them independently.

The team has also had the honour of hosting webinars with renowned industrialists and entrepreneurs in Pakistan’s budding commercial aviation industry such as Mr Raja Khan, CEO of Integrated Dynamics and Dr Sarah Qureshi, developer of the world’s first contrailless aircraft engine and CEO of Aero Engine Craft Ltd.

Drones are revolutionizing the face of work in every sector imaginable. Farmers can use drones to perform in-depth analyses on crop and soil health that give them insights into how much sunlight particular plants are absorbing or the water content of a patch of land. Pre-planning surveys carried out with drones can cover areas of land in hours that would take workers days to cover.

These also provide detailed maps that can help in everything from mine-planning and pipe-laying to construction and real estate development. Drones make on-site operations safer and more efficient by enabling routine inspections and monitoring without halting work or risking employee safety.

Pakistan is seeing an increasing trend of UAV implementation in the commercial and civil sector from 2019 onwards. Drones cut down costs, save time and improve operations. Most service providing companies have to import their drones from overseas which drives up costs.

Local UAV design and development remains an as of yet under-explored potential sector in Pakistan. That is where NUST Airworks aims to step in and provide the required talent. The team is committed to developing and nurturing talent that can propel UAV technology forward in the country.

Submitted by: Fatima Shafique, Team NUST Airworks

![]()